The Impact of AI in Manufacturing

Revolutionizing the Industry for Tool & Die and Automation Manufacturers

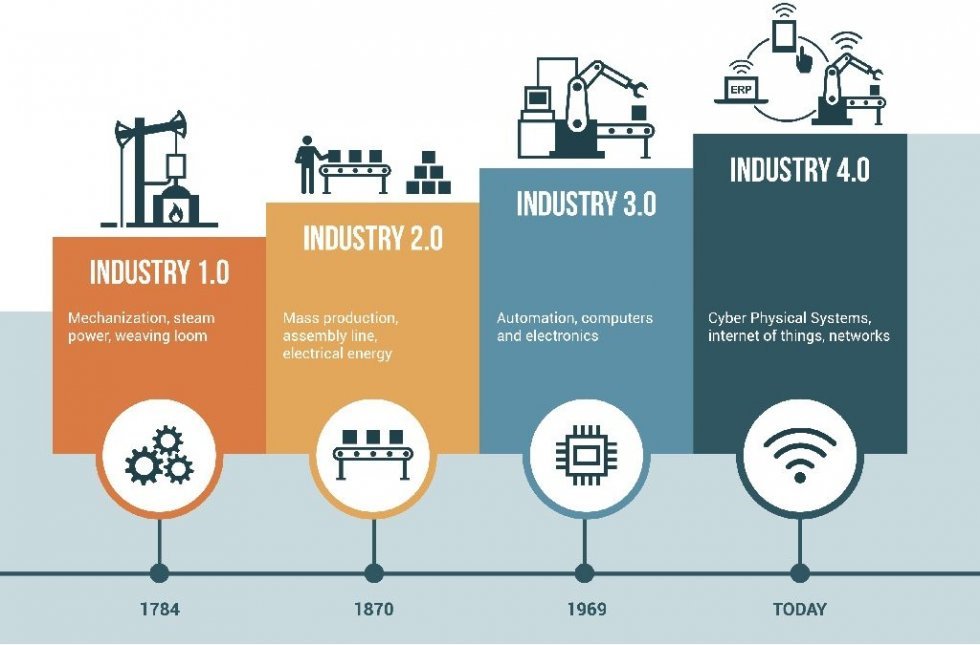

Artificial intelligence (AI) – a term that once seemed relegated to science fiction – is now a reality that is reshaping various industries, including manufacturing. The introduction of AI in manufacturing has been nothing short of revolutionary, bringing about radical changes in the way we produce, process, and automate things. With AI, the manufacturing industry is witnessing unprecedented levels of efficiency and productivity, which were unimaginable a few decades ago.

The infusion of AI in manufacturing isn’t just about automating repetitive tasks. It’s about leveraging smart algorithms, machine learning techniques, and data analytics to improve operational efficiency, reduce downtime, predict maintenance issues, and enhance overall product quality. From predictive maintenance to smart inventory management, AI is initiating a profound transformation in manufacturing. This shift is reshaping the industry by enhancing operational efficiency, boosting productivity, and fostering innovation.

As we delve deeper into the world of AI and manufacturing, we will explore how this technology is revolutionizing the Tool & Die and Custom Automation sectors. We will look at the benefits, case studies, top AI manufacturing companies, and future predictions and trends of AI in manufacturing.

Understanding Artificial Intelligence (AI) and its Relevance in Manufacturing

Artificial intelligence, or AI, is a field of computer science that aims to create intelligent machines that work and react like humans. AI is not just a single technology, but a collection of technologies, such as machine learning (ML), natural language processing (NLP), and robotics, that are designed to simulate human intelligence.

In the context of manufacturing, AI represents a new paradigm. It enables machines to analyze vast amounts of data to identify patterns, learn from experience, and make predictions, all without human intervention. This autonomous nature of AI is what makes it a game changer for the manufacturing industry.

AI’s relevance in manufacturing cannot be overstated. It offers immense potential for improving operational efficiency, enhancing product quality, and reducing costs. By harnessing the power of AI, manufacturers can optimize their production processes, anticipate maintenance needs, and make smarter decisions about resource allocation.

The Role of AI in Tool & Die and Custom Automation Manufacturing

AI plays a significant role in the Tool & Die and Custom Automation manufacturing sectors. In Tool & Die manufacturing, AI helps in predicting tool wear and failure, which allows for proactive maintenance and reduced downtime. Machine learning algorithms can analyze data from sensors embedded in machinery to predict when a tool is likely to fail. This enables manufacturers to replace or repair the tool before it breaks, thereby preventing costly production delays.

In Custom Automation manufacturing, AI is used to enhance the efficiency and precision of automated systems. Through machine learning, automated systems can adapt to variable conditions and improve their performance over time. For instance, AI can enable a robotic arm to adjust its movements based on the specific characteristics of the items it’s handling, thereby increasing accuracy and reducing the risk of errors.

Companies are using AI to enhance their operations and processes. One significant application is in creating optimization plans. This involves utilizing AI’s capabilities to analyze complex production data and generate effective strategies for streamlining operations and reducing waste. Software such as ChatGPT and Writesonic can be used for enhancing communication and collaboration in the manufacturing environment. This can be particularly useful in large companies where clear and immediate communication can greatly impact efficiency.

AI and Manufacturing: Exploring the Connection

AI in manufacturing is the integration of intelligent algorithms into manufacturing equipment, enabling them to learn from experiences and make independent decisions. These smart machines not only input or output data but also leverage data from various sources to provide an ‘intelligent’ response, almost akin to human behavior in terms of decision-making and other tasks.

The rise of AI in manufacturing has been spurred by two main types of Machine Learning techniques—supervised and unsupervised. The choice of technique hinges on the nature of the data and the organization’s goal in data analysis.

Supervised Machine Learning

This type of Machine Learning employs labeled datasets to train the algorithm, aiming to predict the outcome of new data. It allows direct feedback to verify the correctness of its output prediction. Hence, supervised learning models are more suited for tasks involving predictive analytics and object recognition.

Unsupervised Machine Learning

Unsupervised machine learning models, on the other hand, operate on unlabeled input data. Instead of seeking to predict outcomes, these models aim to discover hidden patterns and unknown trends in the data. In essence, they learn through trial and error, much like a child does, making them ideal for anomaly detection and advanced factory monitoring systems.

Benefits of Using AI in Manufacturing

The benefits of using AI in manufacturing are wide-ranging and substantial. First and foremost, AI can significantly enhance productivity. By automating mundane tasks, AI allows human workers to focus on more complex and critical tasks, thereby increasing overall productivity.

Secondly, AI can drastically reduce downtime. By predicting maintenance needs, AI helps manufacturers avoid unexpected machine failures and associated production delays. This results in significant cost savings and improved operational efficiency.

Thirdly, AI can enhance product quality. By analyzing data from various stages of the production process, AI can identify quality issues and suggest corrective actions. This leads to better quality products and higher customer satisfaction.

AI also plays a crucial role in improving safety in the manufacturing industry. AI-powered robots can perform dangerous tasks that would be hazardous for human workers. This not only enhances worker safety but also helps manufacturers comply with safety regulations.

Challenges with AI

The integration of AI in manufacturing, though beneficial, does come with a set of challenges. First, the complexity of AI technology can be a significant barrier to its broad adoption. Manufacturers often lack trust in the capabilities of AI, which can hinder its successful implementation. Secondly, concerns about data security and risk mitigation are prevalent, making it crucial for companies to establish robust security protocols. Finally, there’s the challenge of ensuring transparency. Since AI systems are typically ‘black boxes’, it can be difficult for manufacturers to understand and explain how AI-based decisions are made. This lack of transparency can lead to trust issues and resistance to AI adoption.

Case studies: How AI is Revolutionizing Industries

The impact of AI in manufacturing is not just theoretical; it’s practical and evident in various industries. Let’s look at a few case studies that highlight how AI is revolutionizing industries.

In the automotive industry, AI is used to optimize production processes and enhance product quality. For instance, Toyota uses AI to predict the wear and tear of machine tools in its production lines. This helps the company prevent unexpected machine failures and maintain a high level of operational efficiency.

In the electronics industry, companies like Intel use AI to analyze data from their manufacturing processes and identify potential quality issues. By addressing these issues proactively, Intel is able to maintain a high standard of product quality and customer satisfaction.

In the aerospace industry, companies like Airbus use AI to optimize their supply chain operations. Through machine learning algorithms, Airbus can predict demand for various parts and optimize its inventory accordingly. This reduces costs and improves operational efficiency.

The Top AI Manufacturing Companies and Their Contributions

Several AI manufacturing companies are leading the charge in revolutionizing the industry. Companies like Siemens, IBM, and Microsoft are making significant contributions to the field of AI in manufacturing.

IBM

IBM’s Watson IoT platform offers AI-powered solutions that enable manufacturers to analyze data from their operations and make smarter decisions. IBM’s AI solutions are used in various sectors, including oil and gas, chemicals, and food and beverage.

Microsoft

Microsofts Azure AI platform provides AI solutions that help manufacturers improve operational efficiency, enhance product quality, and reduce costs. Microsoft’s AI solutions are used in various industries, including healthcare, retail, and manufacturing.

Siemens

Siemens has developed a range of applications for Machine Learning solutions in manufacturing. They have created an ML model that uses artificial neural networks, allowing robotic devices to learn and adjust to new requirements similar to humans. Siemens also designs applications for large-format manufacturing, such as oil and gas. By monitoring variables like torque and heat, these applications can predict equipment failure and devise solutions to mitigate these problems. With its Digital Industries Software, Siemens provides AI solutions that help manufacturers optimize their production processes, predict maintenance needs, and enhance product quality. The company’s AI solutions are used in various industries, including automotive, electronics, and aerospace.

General Electric

General Electric (GE) has developed applications focused on manufacturing asset management using supervised and unsupervised machine learning algorithms to analyze structured and unstructured data. These applications can be used for predictive and prescriptive maintenance advances to improve the lifespan and usefulness of OEM equipment.

Fanuc

Fanuc’s machine learning and AI applications focus heavily on robotics. Based on unsupervised machine learning algorithms, they have developed robots that can learn a task from scratch and quickly master it. This application is ideal for remote manufacturing and heavy assembly industries. Fanuc also extends these deep learning algorithms for equipment failure prediction in industries like CNC machining.

The Future of AI for Manufacturing: Predictions and Trends

The future of AI for manufacturing looks promising. As AI technologies evolve and mature, their impact on the manufacturing industry is expected to grow. When combined with the power of the Industrial Internet of Things (IIoT), AI can create a fully automated, smart factory. This union can increase production capacity with a minimum additional cost, improve quality and customer satisfaction, and speed up production relative to high production quality.

Here are a few predictions and trends for the future of AI in manufacturing.

Firstly, the use of AI in manufacturing is expected to become more prevalent. As more manufacturers realize the benefits of AI, they are likely to adopt AI technologies in their operations.

Secondly, AI is expected to play a bigger role in predictive maintenance. With advancements in machine learning algorithms and sensor technologies, AI’s ability to predict maintenance needs is expected to improve.

Thirdly, AI is expected to enable more personalized manufacturing. Through AI, manufacturers can analyze customer data and tailor their products to meet specific customer needs. This could lead to a new era of personalized manufacturing.

Challenges and Solutions When Integrating AI in Manufacturing

Despite its numerous benefits, integrating AI in manufacturing is not without challenges. One of the main challenges is the lack of understanding of AI and its potential applications in manufacturing. This often leads to resistance from employees and a lack of buy-in from management.

Another challenge is the lack of skilled professionals who can develop and implement AI solutions. This skills gap can hinder the adoption of AI in manufacturing.

However, these challenges are not insurmountable. To overcome the lack of understanding about AI, companies can invest in training and education for their employees. This can help dispel misconceptions about AI and foster a culture of innovation.

To address the skills gap, companies can collaborate with universities and research institutions to develop talent in AI. They can also hire consultants or outsource their AI projects to specialized AI companies.

Steps to Implement AI in Manufacturing Processes

- Identify the Areas: First, identify the areas in your manufacturing process that can benefit from AI. These could include quality assurance, predictive maintenance, supply chain management, or production planning.

- Collect and Analyze Data: AI models need data to learn from. Collect data from your manufacturing process such as production volume, downtime, equipment failures, etc. Then analyze this data to understand the patterns and correlations.

- Choose the Right AI Technology: Depending on your needs, you may choose different AI technologies. For example, Machine Learning can be used for predictive maintenance, while Robotics Process Automation (RPA) can automate repetitive tasks.

- Develop or Adopt an AI Model: Depending on your resources and expertise, you may choose to develop your own AI model or adopt an existing one. You can use platforms like TensorFlow or PyTorch for development.

- Train the AI Model: Use your collected data to train the AI model. This involves feeding the data into the model and adjusting the model’s parameters until it can accurately predict outcomes.

- Deploy the AI Model: Once the model is trained and tested, you can deploy it into your manufacturing process. Monitor the model’s performance and adjust it as necessary.

- Iterate and Improve: AI implementation is a continuous process. Keep collecting data and retraining your model to improve its accuracy and efficiency.

Conclusion: Embracing AI for Manufacturing Transformation

The impact of AI in manufacturing is profound. From enhancing productivity to improving product quality, AI is revolutionizing the way we manufacture goods. While there are challenges in integrating AI in manufacturing, the potential benefits far outweigh these challenges.

As we look to the future, the role of AI in manufacturing is likely to grow. Whether it’s in predictive maintenance, personalized manufacturing, or any other area, AI holds immense potential for transforming the manufacturing industry.

Embracing AI is not just about adopting new technologies; it’s about embracing a new way of doing things. It’s about leveraging the power of data and analytics to make smarter decisions and optimize operations. It’s about creating a culture of innovation and continuous improvement.

As manufacturers, we have the opportunity to be at the forefront of this AI revolution. By embracing AI, we can transform our operations, deliver better products, and create a sustainable future for our industry. The future of manufacturing is here, and it’s powered by AI.