Innovate or Get Left Behind

How Manufacturing Technologies Can Help Create a Culture of Innovation in Your Business

In the ever-evolving world of business, one thing remains constant: the need for innovation. This is particularly true in the manufacturing industry, where competition is fierce and the pace of change is relentless. Manufacturing innovation is no longer a luxury; it’s a necessity for businesses that want to stay ahead of the curve and maintain their competitive edge. The key to fostering innovation lies in the adoption of advanced manufacturing technologies. These cutting-edge tools and techniques enable companies to streamline their operations, reduce costs, and improve overall performance, ultimately driving business growth and success.

In this article, we’ll explore the critical role that manufacturing technologies play in fostering innovation, and discuss how you can harness their power to create a culture of innovation within your business. We’ll also delve into some manufacturing technologies examples and their impact on businesses, as well as new manufacturing technology trends to watch for. Finally, we’ll outline steps you can take to create a culture of innovation in your business and discuss the future of manufacturing technologies and innovation.

The Role of manufacturing technologies in fostering innovation

Manufacturing technologies are the lifeblood of innovation in the industry. They enable businesses to improve efficiency, quality, and flexibility while reducing costs and waste. This, in turn, allows companies to develop new products and processes, explore new markets, and stay ahead of their competitors.

There are several ways in which manufacturing technologies can foster innovation. Firstly, they can help companies to automate repetitive tasks, freeing up employees to focus on more creative and strategic activities. This not only increases productivity but also enables businesses to tap into the full potential of their workforce, fostering a culture of continuous improvement and innovation.

Secondly, manufacturing technologies can facilitate collaboration and information sharing across departments and even across different companies. By breaking down silos and encouraging open communication, these technologies can help to spark new ideas and drive innovation from the ground up.

Finally, manufacturing technologies can enable companies to make better use of data, analytics, and insights, helping them to identify areas for improvement and make more informed decisions about their operations. This data-driven approach to innovation can lead to significant improvements in efficiency, quality, and overall performance.

Manufacturing technologies examples and their impact on businesses

There are countless examples of manufacturing technologies that have had a transformative impact on businesses, driving innovation and helping them to stay ahead of the competition. Here are just a few:

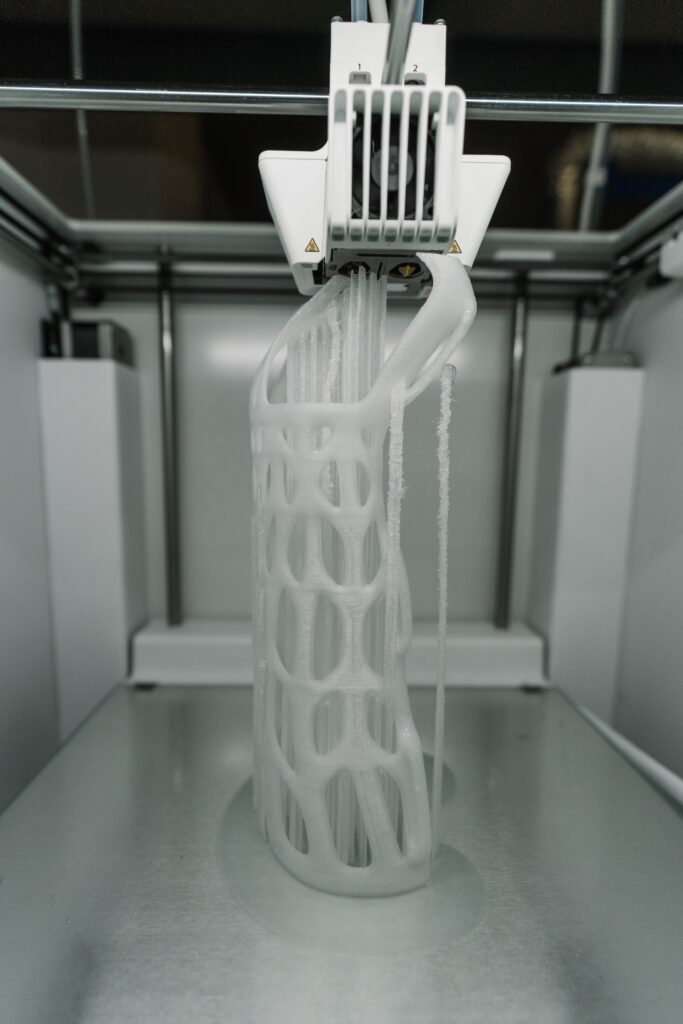

- 3D Printing: Also known as additive manufacturing, 3D printing has revolutionized the way products are designed, prototyped, and produced. By allowing companies to create prototypes in-house and manufacture products on demand, this technology has dramatically reduced lead times, costs, and waste.

- Industrial Robotics: The use of industrial robots has become increasingly common in manufacturing, enabling businesses to automate repetitive tasks, improve efficiency and quality, and reduce costs. As a result, companies can focus on developing new products and processes, driving innovation forward.

- Internet of Things (IoT): IoT technology helps businesses to connect their devices, machines, and systems, enabling them to collect, analyze, and act on real-time data. This can lead to significant improvements in operational efficiency, product quality, and overall performance, driving innovation and growth.

New manufacturing technology trends to watch for

As technology continues to advance, new manufacturing trends are emerging that have the potential to reshape the industry and drive innovation even further. Here are a few to keep an eye on:

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning can help businesses to analyze vast amounts of data and identify patterns and trends, enabling them to make more informed decisions about their operations. This can lead to significant improvements in efficiency, quality, and overall performance, driving innovation and growth.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are increasingly being used in manufacturing to provide workers with real-time information and guidance, enabling them to perform tasks more efficiently and accurately. This can lead to significant improvements in productivity and quality, driving innovation and growth.

- Digital Twins: Digital twins are virtual replicas of physical assets or processes that can be used to simulate, predict, and optimize performance. By using digital twins, businesses can gain valuable insights into their operations, enabling them to make more informed decisions and drive innovation.

Process innovation in manufacturing: A game-changer for businesses

Process innovation is the development and implementation of new manufacturing processes that can lead to significant improvements in efficiency, quality, and overall performance. By embracing process innovation, businesses can stay ahead of the competition, reduce costs, and drive growth.

Some examples of process innovation in manufacturing include the adoption of lean manufacturing principles, the implementation of advanced quality management systems, and the development of new production techniques, such as mass customization.

Integrating technology in manufacturing for better results

Technology plays a crucial role in driving process innovation in manufacturing. By adopting advanced manufacturing technologies, businesses can streamline their operations, reduce costs, and improve overall performance, ultimately driving business growth and success.

Some examples of technology-driven process innovation in manufacturing include the use of automation and robotics to increase efficiency and reduce costs, the implementation of IoT technology to enable real-time data collection and analysis, and the adoption of AI and machine learning to optimize production processes.

New manufacturing processes for a competitive edge

In order to maintain a competitive edge in the manufacturing industry, businesses must constantly adapt and evolve. This often involves developing and implementing new manufacturing processes that can improve efficiency, quality, and overall performance.

Some examples of new manufacturing processes that can give businesses a competitive edge include:

- Additive Manufacturing: Additive manufacturing, or 3D printing, allows businesses to create products quickly and cost-effectively, without the need for expensive molds or tooling. This can lead to significant cost savings and improved product quality, giving businesses a competitive advantage in the market.

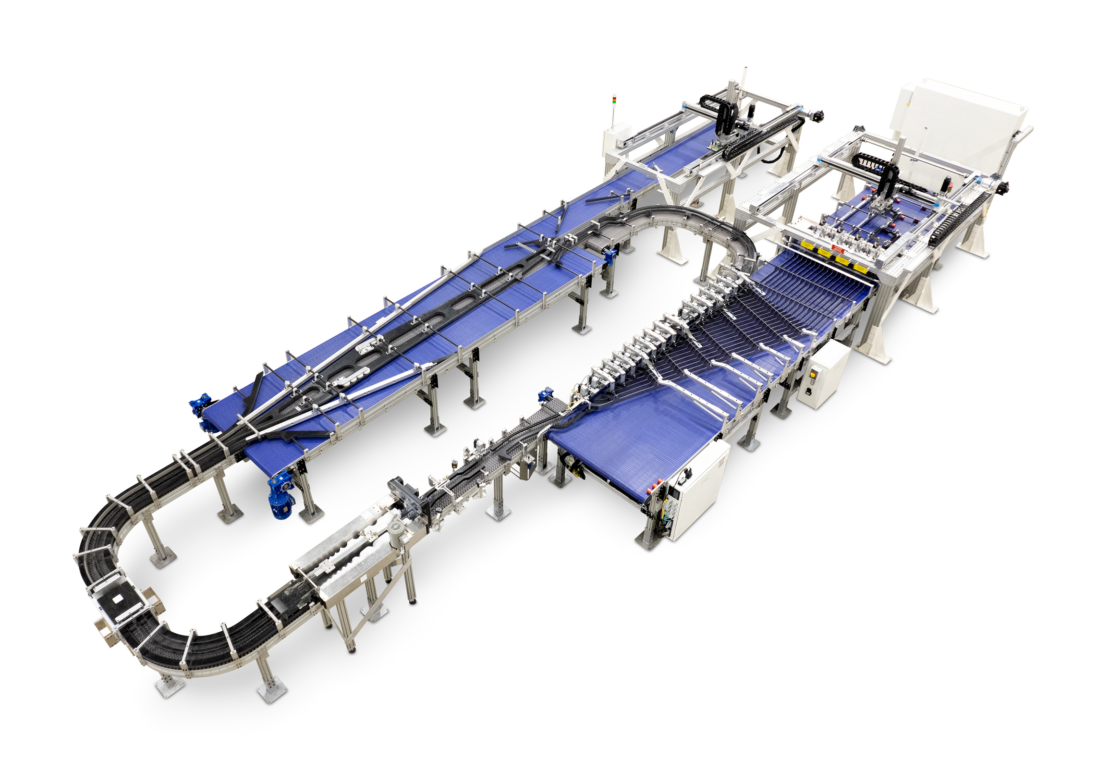

- Flexible Manufacturing Systems: Flexible manufacturing systems enable businesses to adapt their production processes to meet changing customer needs and market conditions. By implementing flexible manufacturing systems, businesses can reduce lead times, improve responsiveness, and drive innovation.

- Green Manufacturing: Green manufacturing involves the development and implementation of environmentally friendly production processes and materials. By adopting green manufacturing practices, businesses can reduce their environmental impact, improve their brand reputation, and potentially access new markets and customers.

Production technology examples driving innovation

There are numerous examples of production technology that have driven innovation in the manufacturing industry. Some of these include:

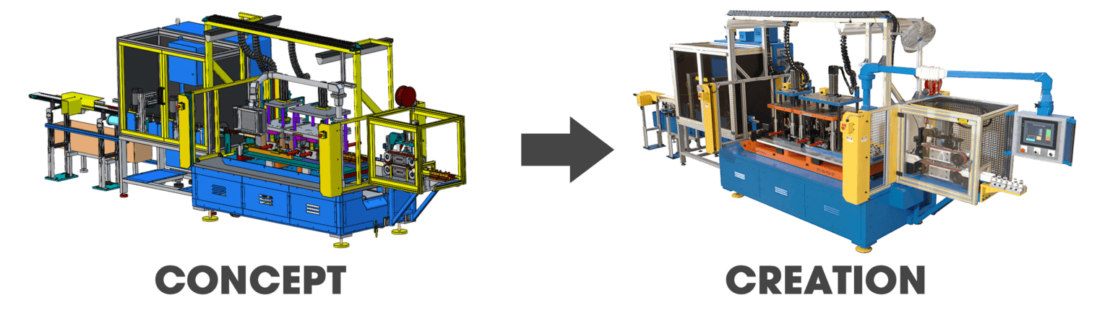

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD and CAM software enable businesses to design, prototype, and manufacture products more efficiently and accurately, leading to significant improvements in product quality and overall performance.

- Smart Factories: Smart factories leverage advanced manufacturing technologies, such as IoT, AI, and robotics, to create highly automated and connected production environments. These technologies enable businesses to improve efficiency, reduce costs, and drive innovation.

- Nanotechnology: Nanotechnology involves the manipulation of materials at the atomic or molecular level and has numerous applications in manufacturing, such as the development of advanced materials and coatings that can improve product performance and durability.

Steps to create a culture of innovation in your business

Creating a culture of innovation in your business involves more than just investing in the latest manufacturing technologies. Here are some steps you can take to foster a culture of innovation within your organization:

- Encourage collaboration and communication across departments and teams, as well as with external partners.

- Invest in employee training and development to ensure your workforce has the skills and knowledge required to drive innovation.

- Foster a culture of continuous improvement, where employees are encouraged to identify and act on opportunities for innovation.

- Implement processes and systems that enable the efficient sharing of information and ideas, such as knowledge management systems and collaboration tools.

- Recognize and reward innovation, both in terms of individual achievements and company-wide successes.

The future of manufacturing technologies and innovation

The future of manufacturing technologies and innovation is bright, with advances in areas such as AI, IoT, and 3D printing set to reshape the industry and drive new levels of efficiency, quality, and performance. As businesses continue to adopt these technologies and embrace process innovation, they will be better equipped to stay ahead of the competition and drive growth.

However, it’s important to remember that innovation is not just about technology; it’s about people. To truly create a culture of innovation, businesses must nurture their workforce and create an environment that encourages collaboration, creativity, and continuous improvement. By doing so, they can harness the power of manufacturing technologies to drive innovation and achieve long-term success.

Manufacturing technologies are a critical enabler of innovation in the industry. From 3D printing to AI, these cutting-edge tools and techniques are transforming the way businesses operate, driving efficiency, quality, and growth. By embracing these technologies, and fostering a culture of innovation within their organizations, businesses can stay ahead of the curve and maintain their competitive edge in an ever-evolving market. The future of manufacturing technologies and innovation is bright, and businesses that embrace this future will be well-positioned for success.