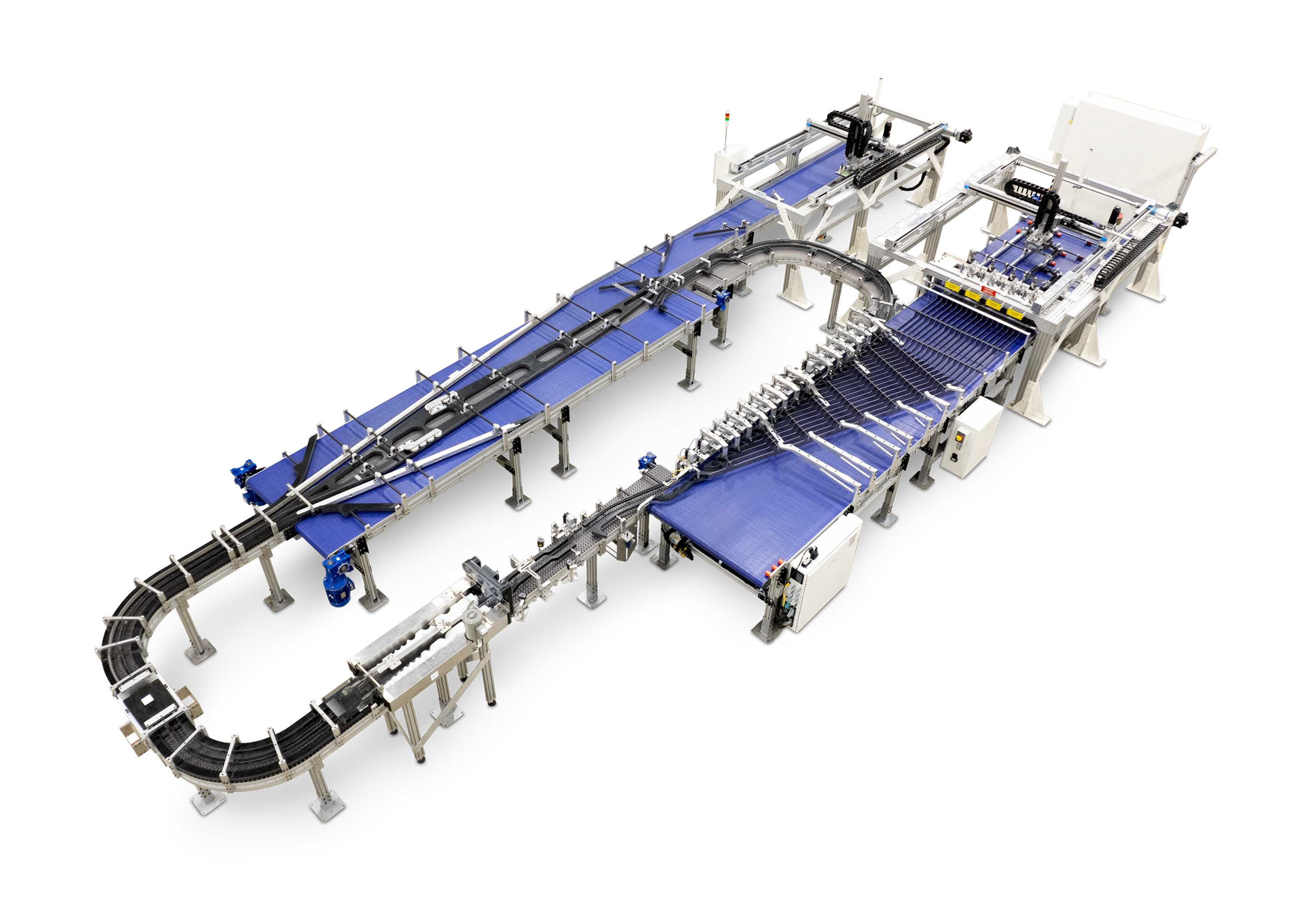

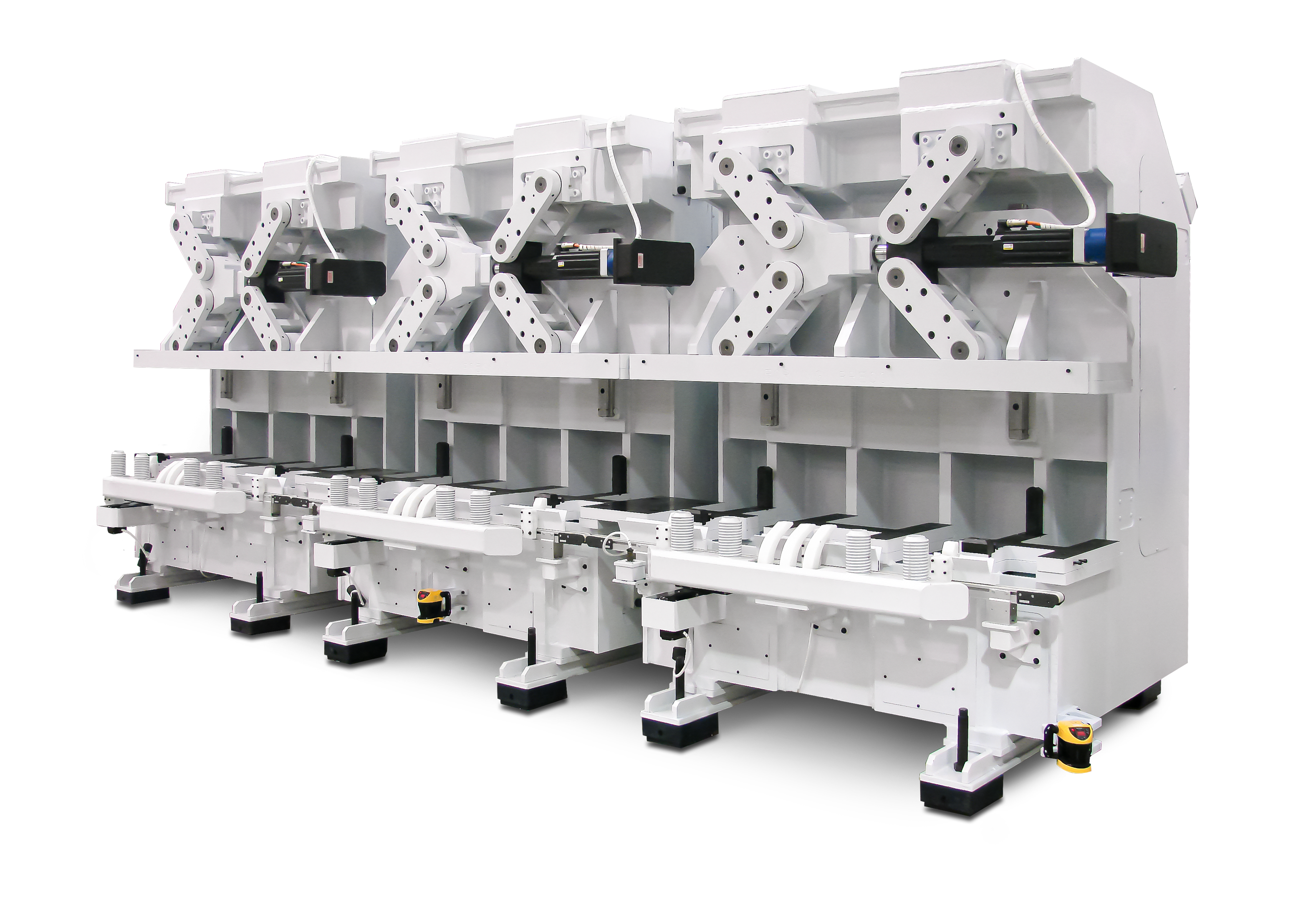

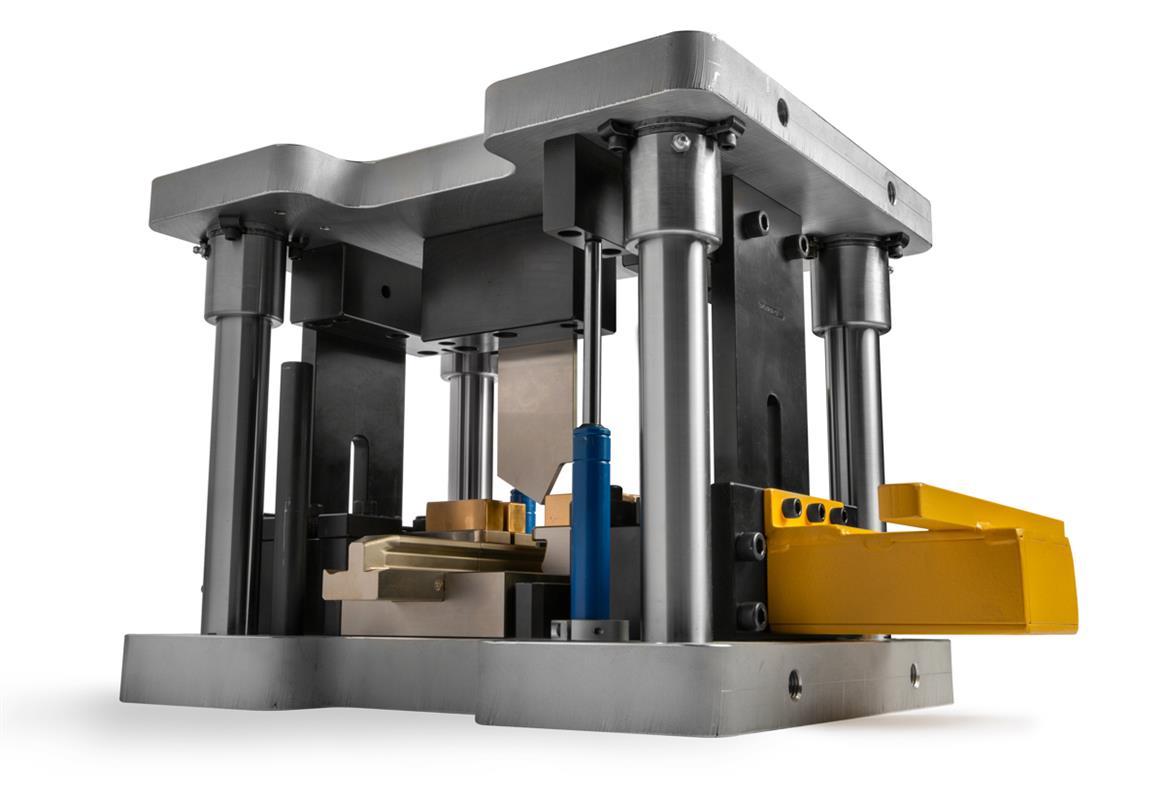

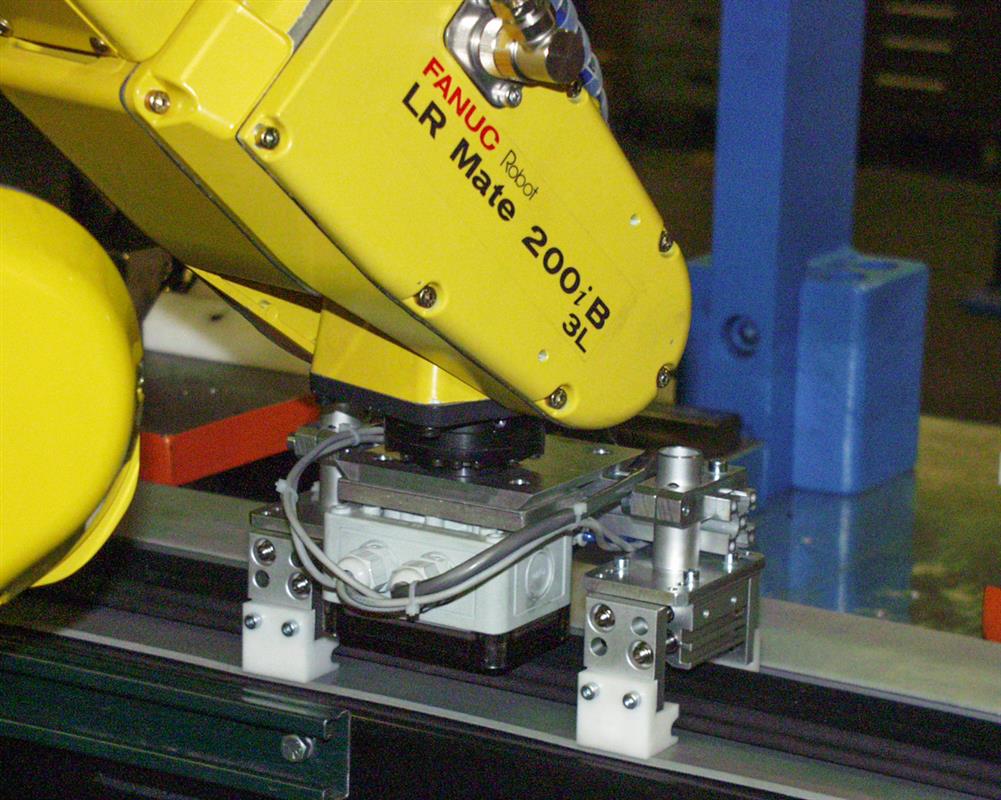

As a leading tool & die manufacturer, EagleMatic takes pride in offering a comprehensive range of exemplary tool and die shop services. Our expertise lies in the design and build of new tooling, setting us apart in the industry. Our experienced die designers bring innovative ideas to each custom-ordered part, ensuring the finest quality product. From part print to finished part, we have the capability to build your tools entirely in-house. Our commitment to excellence and customer satisfaction drives us to continuously improve our die-making processes, ensuring that we deliver the highest quality products to our clients.

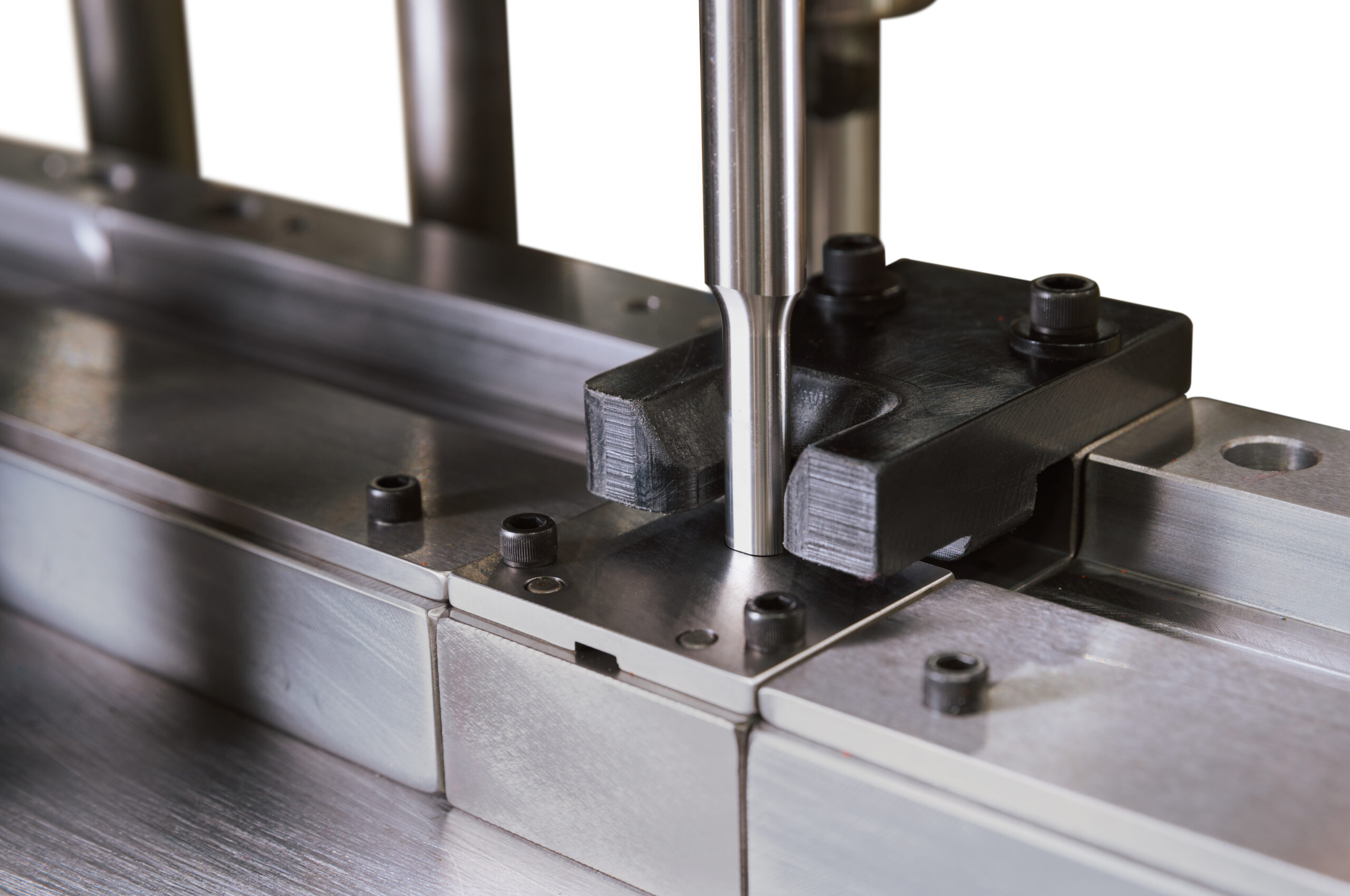

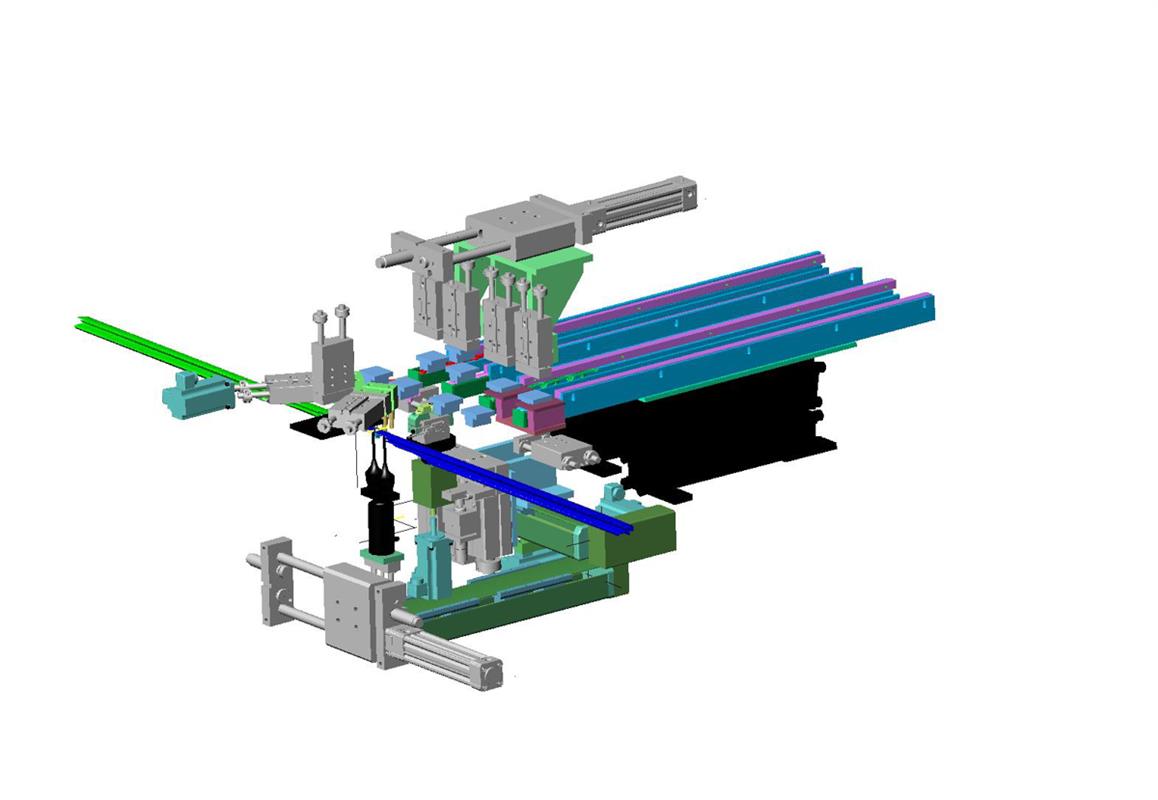

Quality is at the forefront of our approach, encompassing every stage from prototype and validation to installation. Leveraging advanced technology and innovative systems, we design, test, and manufacture high-quality tooling. Our services include Die Simulation, 3D CAD Modeling, and Die Design, with all of the components CNC machined for unsurpassed accuracy. Our skilled tool and die makers, assemble and validate the tooling during the manufacturing process, supported by our cross-functional team utilizing the latest computerized scanning and inspection technologies for precision and durability. At EagleMatic, we are dedicated to upholding the highest standards of quality and precision in our manufacturing process.

Furthermore, our engineers employ cutting-edge technology and software to perform simulations for successful tooling designs and material selections. Our Die Simulation process guarantees that the production material, product geometry, and tool process can withstand the demands of the production environment. We address common problem areas during Die Simulation, ensuring optimal performance and reliability. By integrating the latest advancements in tool and die-making technology, we ensure that our customers receive products that are not only of the highest quality but also meet their specific requirements.